Unified management of multiple warehouses both domestically and internationally

Flexible multi-warehouse management

Physical warehouses, logical warehouses, and channel warehouses, establish logical warehouses based on regions and different logics, to achieve the binding of multiple warehouse locations with SKUs, and flexible inventory checks and transfers

Real-time inventory synchronization

Detailed listing of the carrier's mode of transport, service scope, service level and other information, to facilitate internal coordination between operations and logistics managers

Inventory, sales, and procurement full process management

The whole process management in and out of the warehouse

Inbound and outbound orders are bound to actual business order numbers such as purchase, transfer, inventory, return to the factory for maintenance, return to the supplier, and return to ensure data consistency

First in first out automatic surplus

Clear inventory ledger alignment of current inventory and batch inventory data, procurement requirements, first-in first-out principle update sales progress, to avoid stock shortage or misappropriation

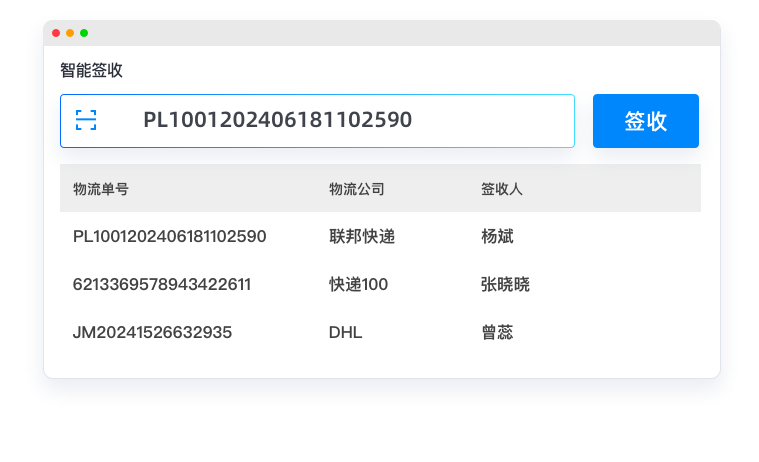

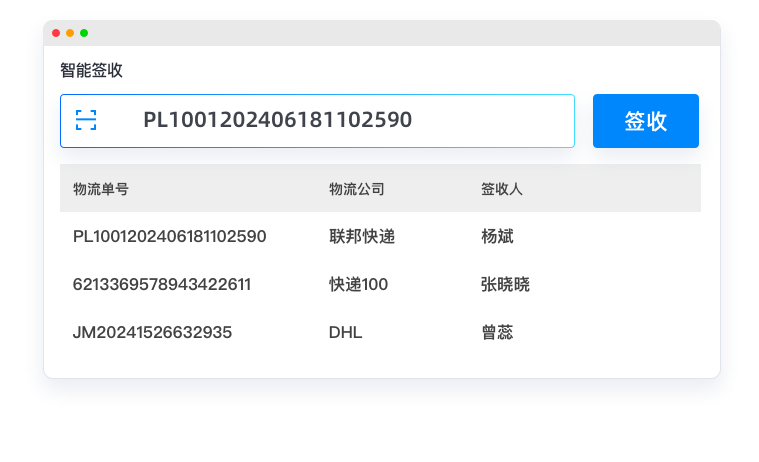

Intelligent signature confirmation/paperless distribution management

Intelligent signature confirmation

Batch processing of purchase receipts, automatic order status update with barcode scanning, saving each receipt record, and optimizing and upgrading the receipt process

Paperless distribution management

PDA (Personal Digital Assistant) planning work paths and product recognition to achieve paperless office operations, with various sorting modes to improve employee efficiency and reduce error rates

Easy maintenance and high scalability

Easy maintenance and high scalability

7x24 hours smooth operation

7x24 hours smooth operation

Ensure data security

Ensure data security

Multi-layer system security protection system

Multi-layer system security protection system

Customer introduction

Customer introduction Face challenges

Face challenges