Customer comments

Customer Introduction

Yinlaite, a top-tier seller in the automotive parts industry with an annual turnover in the hundreds of millions, has established its own overseas warehouses in cities such as Los Angeles and Dallas in the United States. With brands like WQ and KSpeed, they have a large customer base in the European and American markets through channels like Amazon, eBay, and Shopify. Initially focused on traditional trade with a B2B approach, they have now shifted to an online market primarily serving the C-end. As the orders and revenue of the automotive parts industry increase, they also face more and more operational

Facing Challenges

The need for a separate system to print orders for buyers, and the reliance on manual labor to check and align returns with the original order and current inventory stock is difficult to handle.

Box cost control: Unable to automatically match existing boxes based on product size, leading to low utilization of box inventory and cost waste.

Lack of clarity in management across various stages, with no additional perspectives on the arrival progress of goods, making inter-departmental collaboration challenging.

Dependence on offline Excel for management, where supplier price adjustments are not timely, and it is difficult to query, making it impossible to compare purchase prices for the same product.

The finance department cannot timely understand the progress of purchases, and the process of urging delivery is cumbersome and not conducive to bill processing.

Achieving the company's total profit, platform profit, factory warehouse product profit, and long-term annual cost accounting is difficult.

Unable to compare suitable tail-end logistics provider prices, and besides the order dimension, it is difficult to allocate tail-end costs to products for later reasonable control of logistics costs.

Logistics additional costs: For the main platforms, different logistics providers may charge additional fees based on residential delivery locations, which cannot be accounted for in costs, leading to inaccurate financial accounting.

Warehouse procurement still relies on offline communication for new product development, with no archiving and no accountability for subsequent sales.

The current system does not support the accurate handling of partial refund order data, and it is difficult to distinguish who bears the return shipping costs, causing inaccurate financial accounting.

Currently, it is not possible to customize design rules, and the SKUs are numerous and disorganized.

It is not convenient to handle customer inquiries, replies, and email reminders, and it is difficult to intercept orders in a timely manner.

Owners and finance departments find it difficult to quickly understand data from various dimensions, making it hard to make operational decisions through the current system.

Currently using three systems, which are not fully integrated with each other.

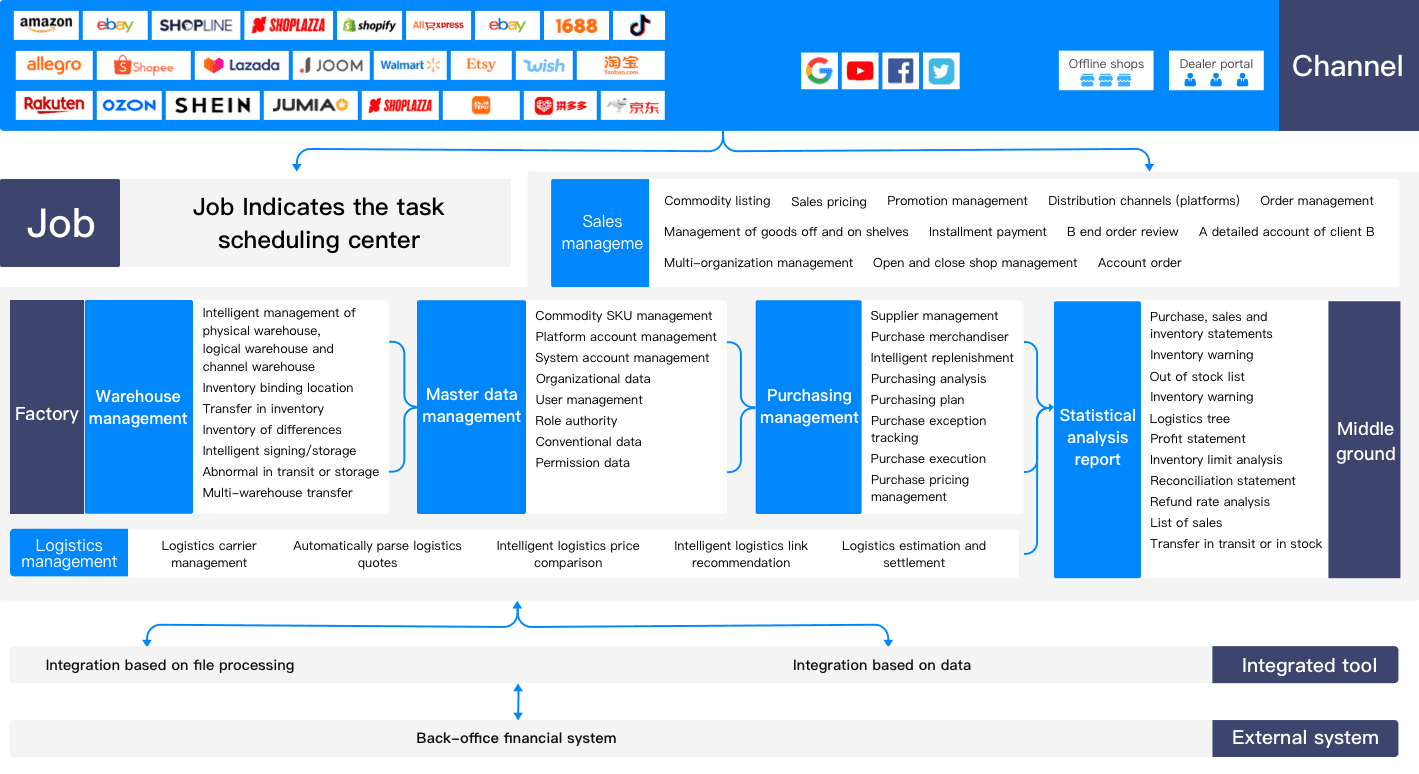

Solution

Value Benefits

Binjiang assists Yinlaite in achieving unified management of suppliers, multi-perspective purchase order tracking, unified management of multiple warehouses to realize real-time synchronization of inventory in domestic and international warehouses, simplification of procurement, warehousing, and shelving processes, refined management of SKUs for products across all channels, support for customer service to handle inquiries from multiple channels synchronously, batch and rapid order printing, effective savings on logistics cost expenditure, breaking data silos while meeting cross-departmental collaboration, and multi-dimensional data reports facilitate profit accounting, making the integration of business and finance easy to achieve.

Looking Ahead to the Future

Binjiang Technology is committed to becoming the most trusted customized solution service provider for cross-border outbound enterprises, helping more automotive parts trade and production enterprises to easily manage domestic and foreign warehouses and accelerate the development of the international market.